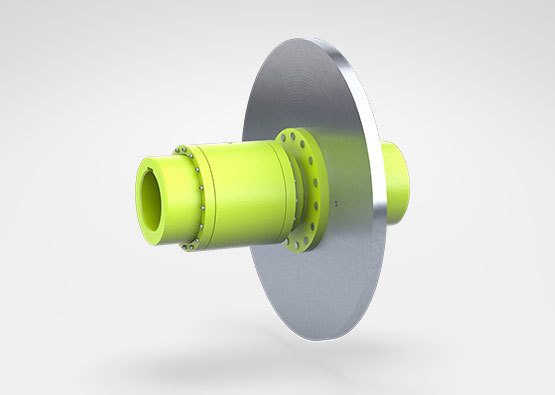

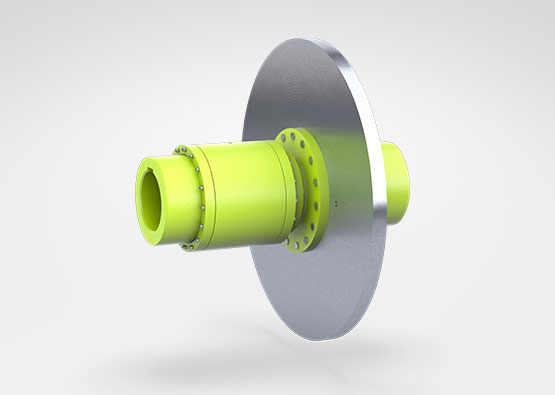

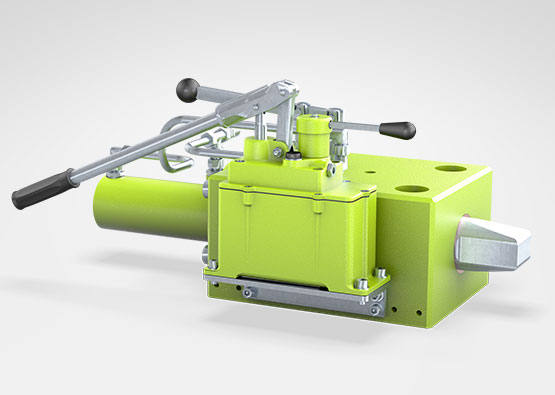

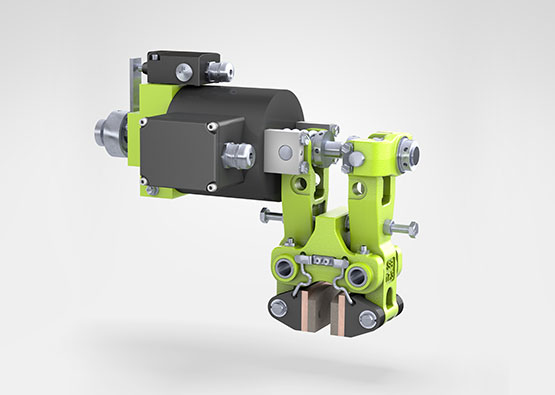

KBT

TKMAX: 46000 Nm

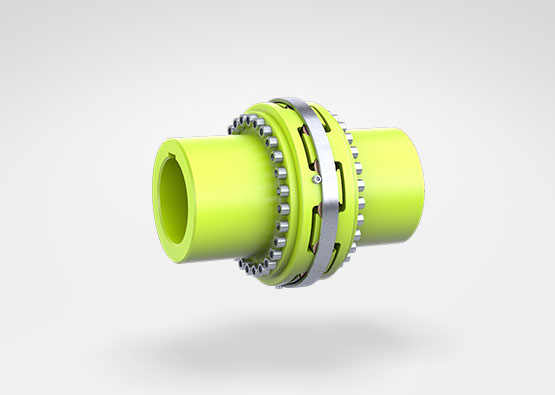

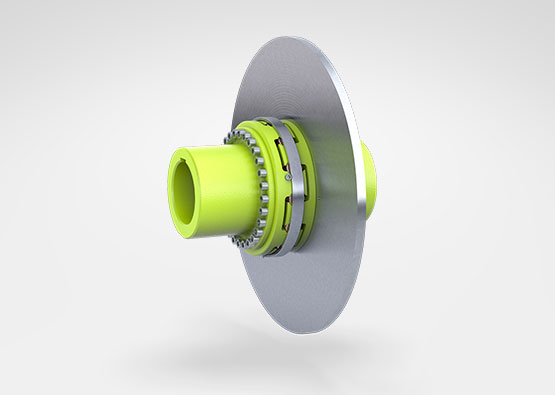

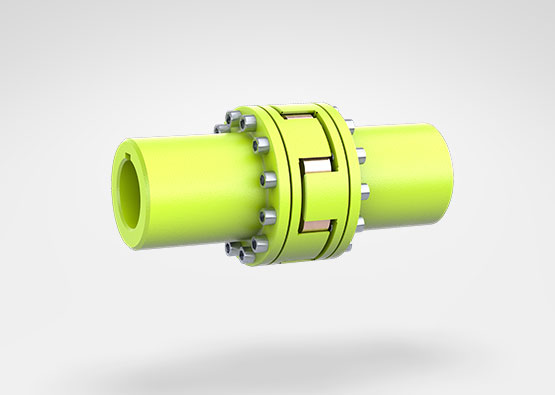

These couplings are for use in machinery where a torsionally rigid torque is required, especially on frequently varying loads and speeds.

- Steel coupling with special tooth pattern

- Torque transmission via internal geared sleeve and external geared hubs

- Replacement of the brake disc or the seals without moving any equipment

- High temperature resistance

- Low wear

- Arrangement of the brake drum on the gear side to allow the brake torque to be maintained when the motor is disengaged

- Vast selection of coupling sizes and brake disc diameters

- Coupling hubs finish bored and keywayed acc. to DIN 6885

- Coupling hubs unbored

- Coupling hubs pilot bored

- Coupling dynamically balanced according to ISO 21940 Grade: G 2.5; G 6.3

- Hubs in special dimensions

- Hubs in special material

- Test certificate DIN EN 10204-3.1

Additional PRODUCTS

- All

- Caliper / Disc Brakes

- Components & Accessories

- Couplings

- Drum & Band Brakes

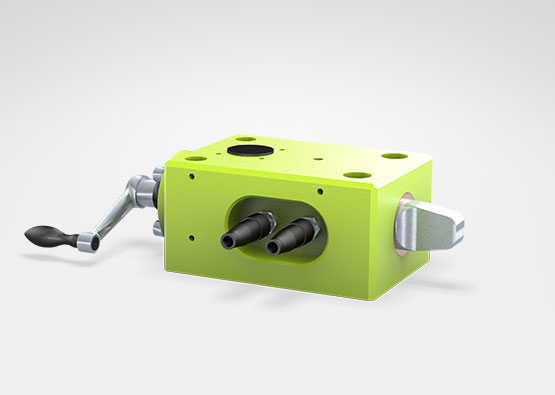

- Hydraulic Systems

- Locking Devices

- Monitoring & Control Systems

- Motor Mounted Brakes

- Pneumatic Drum Clutches & Brakes

- Stop Turn Lock Systems

- Storm Brakes (Rail & Wheel Brakes)

- Thruster / BUEL®

- Wind Turbine Components

- WPT Disc Clutches & Brakes

These couplings are for use in machinery where a torsionally rigid torque is required, especially on frequently varying loads and speeds.

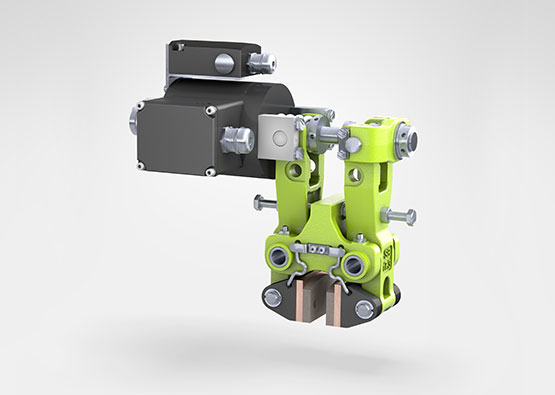

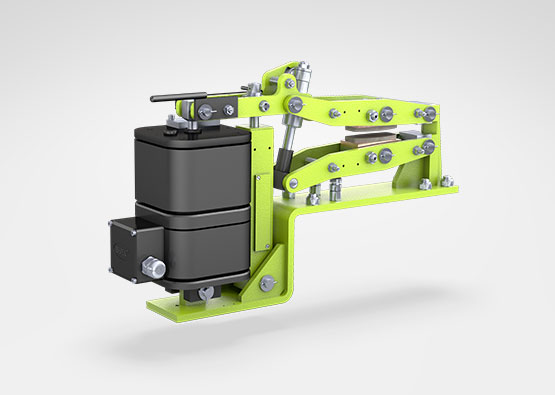

The KFB is a spring applied safety brake which is mainly used in gantry, trolley and hoisting application on harbour crane systems, in dynamic and static use at general industrial applications, in mechanical engineering, steel mills, coal mining or wind energy systems.

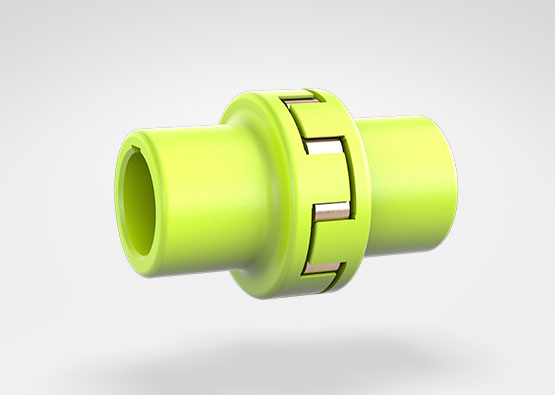

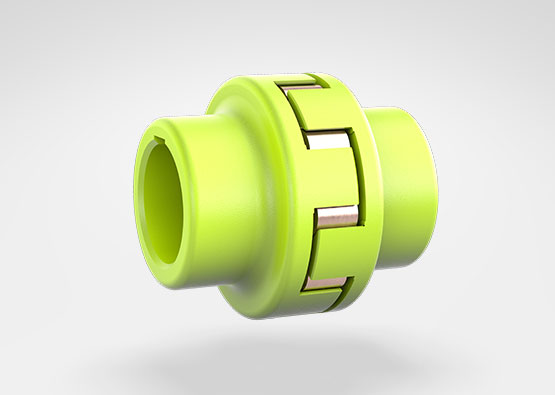

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

These couplings are for use in application with high dynamic loads. Damping of peak torques and vibrations as well as electrical insulation between motor and gearbox are further reasons for the use of this coupling type.

Models within LM series (locking devices) are fail safe and used to mechanically lock a rotational or linear application in a controlled position.

Models within LM sere (locking devices) are fail safe and used to mechanically lock a rotational or linear application in a controlled position.

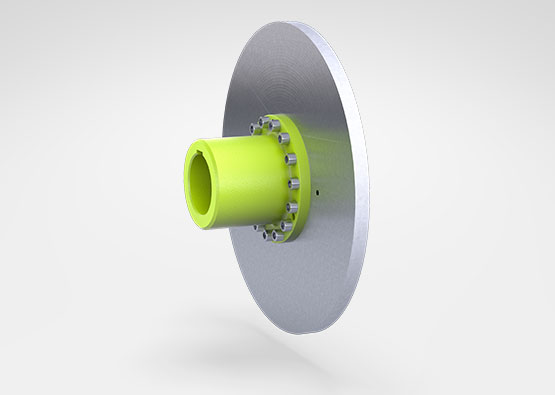

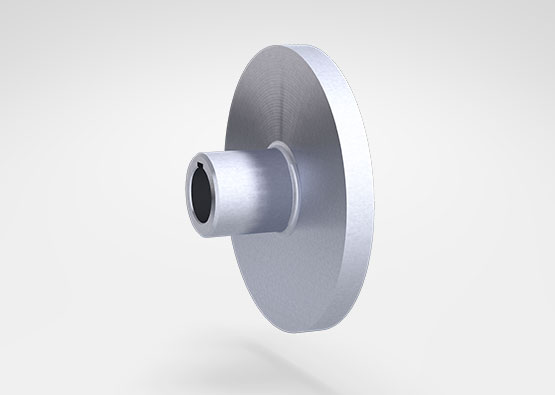

The Hub with Brake Disc Type N + NX is appropriate for all drives, where the brake is not located between motor and gearbox, like brake installation on the second gear box shaft or at the motor end shaft.

Rope drum couplings are recommended for use in hoist mechanisms, winches or conveying applications to connect the gear box output shaft with the rope drum/ winch.

The Hub with Brake Disc Type N + NX is appropriate for all drives, where the brake is not located between motor and gearbox, like brake installation on the second gear box shaft or at the motor end shaft.

The SB 16 brake has a very compact design and is often used on trolleys for container gantry cranes, RTG and RMG equipment

The SB 17.3 MX brake is a spring-actuated, magnetic-return disc brake for trolley applications on container gantry cranes and other port logistics equipment. Furthermore, the very compact design results in a range of industrial applications in various industries

The SB series stands out due to its extremely fast closing times and its variability. It is used in a wide range of industries around the world due to its versatility, ease of application and user-friendly handling.

The SB 22 stands out due to its extremely fast closing times and its variability. It is used in a wide range of industries around the world due to its versatility, ease of application and user-friendly handling.

The SB 23.3 stands out due to its extremely fast closing times and its variability. It is used in a wide range of industries around the world due to its versatility, ease of application and user-friendly handling.

Supported by decades of engineering, evolution, and innovation, the SB 28.5 brake presents significant advantages with an enhanced and compact design, sustainability, and preeminent performance.